Look after your drill core: it’s a resource that keeps on giving

Diamond drilling is always undertaken for the needs of the moment. But fresh-cut rock, in most cases, will last hundreds, if not thousands, of years. Drill core is a resource which can keep on giving as we go back to it again and again with fresh ideas, questions, techniques or agendas. This could be by you or your company, or by other geologists and other companies as the years go by. However, core can only provide this continuing value if indexing and storage systems match the longevity of the core itself.

Roy Woodall, former Exploration Director for Western Mining Corporation said in 1995: “We have re-logged the core from Kambalda (West Australian Ni/Au Camp) three times, and each time we do it, we find a new ore body”.

Drill core is an expensive product providing direct physical sample of the subsurface and will always be an invaluable and irreplaceable resource. As a condition of granting a Mining Lease or Licence to Explore the State should should specify strict enforceable requirements for permanent indexing and storage of core. That core will have cost between $100 – $500 per metre to acquire, so it is not too much to ask that a company spend around $1-$5 per metre extra to properly index and store their product. That company or that geologist might one day themselves be the beneficiaries of similar forethought.

You could be one of them.

I certainly was.

In the mid-1970s, as part of a structural re-assessment of the giant Broken Hill Pb/Zn/Ag mining camp in New South Wales, I had to re-log a number of holes that had been drilled in the 1920s and 1930s. This core was the product of one of the first major diamond drilling campaigns be undertaken in Australia. It was stored in the long-abandoned Consolidated Zinc core yard – an acre of ground on the line-of-lode, sandwiched between old head frames, abandoned machinery and infrastructure, mullock and tailings heaps. The core had been stored in wooden trays laid out in long lines on the ground. Tens of kilometres of core carpeting the entire yard. At the head of each core run a steel stake had been driven into the ground with the hole ID traced on it with solder. Even more importantly, the drillers’ original wooden depth markers had been replaced by small rectangular zinc tags on each of which the hole number and down-hole depth had been stamped by a steel punch.

…in the sea of sand the steel stakes still stood proud…

During a heavy downpour in the 1940s, a nearby fines dump had collapsed and tailings had flowed outwards to cover the yard in fine white sand to depths of up to 50 cm. But in the sea of sand the steel stakes still stood proud, and although not a trace of the original wooden trays remained, with some excavation (you could call it industrial archaeology: the Mining company provided the labour) the core was soon exposed in its original neat parallel rows, as fresh and easy-to-be examined as it had been fifty years before. I mentally thanked the foresight of the long-forgotten project geologist, and remembered the first occasion, seven years before, when I had been given the task of re-logging legacy core.

Rum Jungle, 1967. A mine operated by a subsidiary of Rio Tinto in Australia’s Northern Territory. They were engaged in mining and processing uranium and copper ores from a series of open cuts in the surrounding district . Re-logging old drill core was deemed a suitable task for a rookie geologist. The core had been drilled 5 to 6 years previously and stored in wooden trays stacked over 10 high at the back of an old shed behind the mill. Around 3 kilometres of it. When I pulled back the doors of the shed to let the light in, I found a slope-sided mountain of broken and disorganized core pieces out of which a few bits of rotten, termite-gnawed wood still projected. We organised a front-end loader and quickly transferred the lot to the nearest mullock heap.

…a slope-sided mountain of broken and disoriented core pieces out of which a few bits of rotten, termite-gnawed wood projected…

A few years later, during the nickel exploration boom in Western Australia (1968-71), I frequently scouted old exploration properties abandoned by their former owners. Diamond drill core was left abandoned in the bush, sometimes in their original stacks and sometimes tipped into the nearest gully. The galvanized metal core trays then used were immune to termite attack, but even when stacked, the core was almost as useless as the Northern Territory core described above. The trays were typically in random order, and neither geologist nor driller seemed to have realised (or more likely did not care) that felt or fibre tipped ink marking pens, or painted lines, are not permanently legible, despite what the labeling on the product might say. Exposed to baking heat, rain, UV light and the passage of time, numbers fade and become illegible in a period that can be as short as a few months.

…exposed to baking heat, rain, UV light and the passage of time, numbers quickly fade and become illegible…

Nobody seemed to care that this expensively-acquired product would soon become virtually useless. Or perhaps they did, but reasoned that once they had extracted all the value they could from their one-off pass, no one else – not even themselves - should be given another opportunity. A true dog-in-the-manger attitude.

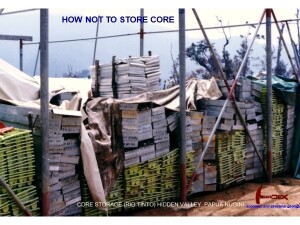

How not to store drill core. In fairness to Rio Tinto, their Hidden Valley project was heroic exploration in an extreme environment near the crest of the Owen Stanley Range. The only access was by helicopter in the brief intervals when the clouds parted and the rain stopped. In the 1990s, after a series of extraordinary force majeur events (Bougainville, Wafi, Mt Kare), Rio took the decision to walk away from all their Papua Nugini operations.

Best practice core storage and labeling. This is core was acquired by the Homestake company from their Trilogy Pb/Zn/Au project in Western Australia. Trays are permanently labelled with riveted metal markers and placed in racks that allow easy individual tray extraction.

I have emphasized how durable diamond drill core is. But sometimes that is not the case..

In the West Java province of Banten, the epithermal gold prospect of Cibaliung was explored with a major diamond drilling program by a junior Australian company during the late 1990s. Many of the rocks on the footwall of the ore body consisted of crumbly acidic clays which swelled to two or three times their volume when exposed to air and moisture. Needless to say, core recovery through these units was poor. I undertook a major re-logging exercise on drill core that was up to 3 years old in order to resolve structure. The core had been stored, according to then best practice, in steel racks under cover, but in a tropical environment it is very difficult to exclude moisture. In the critical section below the ore body, core had expanded to a spongy mass – a gross acidic efflorescence that dissolved the base of the galvanized iron trays cementing them together into an inchoate mass. Pity the poor geologist who had to try to make sense of this stuff (and pity the poor miners who were proposing to develop an underground access decline through it).

…a gross efflorescence had cemented many of the trays together into an inchoate mass…

But you might say, what could anyone do to recover and store drill core from refractory rocks such as these, especially in the heat and humidity of a tropical environment.

Well, there is a way…

2007, Central Thailand. I consulted for the Australian mining company Oxiana (now OZ Minerals) at their Wang Pong epithermal gold exploration project. Oxiana was (and, for all I know, may still be) one of the most technically competent explorers that I have come across .

…one of the most technically competent explorers that I have come across…

Parts of the prospect consisted of swelling acidic clays similar to the problematic rocks that the Indonesian explorers had to deal with. To drill this successfully, Oxiana employed the following strategies:

- Large diameter core (HQ and PQ)

- Triple tube drilling

- Split inner tube for core extraction.

- Wrapping core in clear plastic (industrial strength cling film) to exclude air (see photo)

- Use of plastic core trays (now thankfully becoming an industry standard)

- Long term storage of severely affected sections in sealed shipping containers with nitrogen atmosphere

Note: core wrapped in clear plastic to exclude air and moisture. Twelve metre long racks allow re-assembly of broken core pieces from up to 2 core runs – this facilitates accurate depth measurement and placement of long-core orientation lines

The moral to be taken from the examples above is should be sufficiently obvious.