Aboriginal Heavy Mineral Separation Technology in the Pilbara of Western Australia

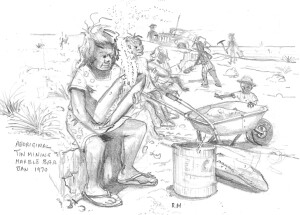

More than 50 years ago I observed a heavy mineral separation technique being practiced by aboriginals in the Pilbara region of Western Australia. The technique was simple, effective and probably unique. I have never seen it described elsewhere even after an extensive search on the net, so I think it important to provide a record of what I saw. Unfortunately, I did not have a camera with me at the time (a video would have been even better) so I base this description on fallible memory, reinforced by a quick sketch of the scene that I made in my notebook some weeks after the event.

Over the summer of 1969-70, I was based for five months in the remote former gold mining town of Nullagine, in the Pilbara region of NW Western Australia.

The local indigenous people were the Martu tribe. Several extended family groups had a semi-permanent camp on the dry bed of the Nullagine River just outside town. They lived on welfare, supplemented with some bush tucker and a bit of dry panning for gold, at which they were expert. The barman at the Conglomerate Hotel in Nullagine would offer credit against payment every second Thursday when social security payments were made at the Post Office. If the slate were not cleared, there would be no more credit. I saw an elderly Martu man, when his credit was cut off late one night, mutter – I will go get some gold. He knew a good patch nearby. An hour later he returned with a teaspoonful of gold dust and fine nuggets wrapped in a fold of paper: maybe a half-ounce altogether. Ted the barman sized the gold up. That’s worth six stubbies, he said, and slid it into a jam jar that he kept under the counter. By the end of my stay in Nullagine Ted had two full jars and had no idea what this was worth (he himself was a recently arrived Englishman), but even at the depressed gold price of 50 years ago, he was clearly ahead. The Martu man seemed satisfied: six bottles of beer for an hours’ easy work was a fair rate for him.

There was no overt segregation or discrimination in Nullagine. The first peoples shopped in the store, drank at the bar, and, when sick, attended the nursing clinic. Since the first arrival of cattlemen in the district in the 1880s, they had long adapted to white settlement. They had also adapted to the previous the gold mining booms of the nineteen hundreds and nineteen thirties which had led to the foundation of Nullagine town and had left it by 1970 (and, indeed, today) as something of a ghost town. Their behavior around town was no better or worse than that the white population, but the white and black populations did not mix – both preferred to keep themselves to themselves.

The Martu people had brilliantly adapted for heavy mineral separation an item of their ancient technology which the local white population called a yandi. Whether that was the term used by the Martu themselves, I do not know. A yandi was traditionally a section of tree bark or hollowed out log, with an open-ended U-section shape, about 50 cm long by 25 cm wide. Women used this tool to separate husks from the kernels of hand-gathered wild grasses. It also doubled as a container for carrying or storing foraged seeds and roots, and the occasional baby. I was told that women could separate salt from sugar with their yandi. I never saw that done – why would anyone bother? I never saw the yandi being used for separating alluvial gold from gravel and sand (there was little incentive to pan gold in 1969: only a few old-timers still practiced the craft), but I did once observe yandies being employed to separate cassiterite crystals from weathered granite regolith in a rich mineralised area that a group of aborigines had discovered near the town of Marble Bar, 100 km north of Nullagine (cassiterite is tin oxide – a heavy, black, crystalline mineral). The State Mining Registrar at Marble Bar [1] had pegged a Mining Lease in their name to protect the group from inevitable claim jumping and had also taken on the role of ensuring that they got a fair price for their product. These are not services normally provided by Mining Registrars. I had traveled to Marble Bar to register a Claim and the Registrar told me about his unique experiment. I decided to go out to see this tin mining operation for myself.

The sketch was completed after I was on site, the details from memory. What stands out is the young woman in the foreground – clearly the champion panner, and apparently in charge of the whole operation, issuing orders to the men doing the muscle work with pick, shovel, sieve and barrow. In the background the Marble Bar storekeeper arrives to collect the week’s product in exchange for goods and grog. Click for a larger image.

There was about a dozen aboriginals at site – men, women and children. Three beat-up old sedans parked to one side. The women, wearing print cotton dresses, were sitting along the edge of the shallow diggings. Each had a yandi made from a sheet of corrugated iron which had been hammered flat then trimmed and folded to shape. They would scoop some dry gravel into the right-hand end of the tool, then, with a hand at each end, toss the dirt into the air to be rapidly caught on the left side of the yandi. A quick sideways shuffle transferred the dirt back again to the right side, and the process was repeated: right to left, then left to right, but in an asymmetric manner, the right hand and arm doing most of the work. A rocking, shuffling motion, hands almost a blur. A long tail of dust drifting away in the dry desert wind.

Hard to analyze the separate movements employed – a side to side shuffle, then a flick, then a catch: shuffle, flick catch again; shuffle, flick, catch. This repeated cycle was interrupted by regular pauses to scrape away excess barren dirt and gravel from the left half of the yandi. After 10 minutes or so, a concentrate of fine black cassiterite crystals (about half a cup) was neatly separated to the right: a residue of barren sand to the left.

The process required technique, skill, effort and concentration. My own efforts (lacking the skill and technique), with a yandi full of high-grade ore, produced only howls of laughter and no separation of anything – apart from me and my dignity.

With the scrub and thin soil was scraped away to expose bedrock, the patches of high-grade ore were very visible – the cassiterite standing out like raisins in a cake. The women’s menfolk dug the weathered granite (2) with picks and shovels, broke down larger lumps with sledgehammers, sieved out a size fraction, then shoveled the dirt into wheelbarrows to transport to their wives The children, some mere toddlers, hand-picked the black crystals from the yandi concentrate and put them into wire-handled buckets made from old 10-gallon oil drums. When full, these weighed around 30kg – about as much as a man could lift.

While I was watching this operation, the Marble Bar storekeeper arrived, his truck laden with mining tools (picks, shovels, crowbars, wheelbarrows), boxes of food and clothing, cartons of beer and flagons of sweet sherry. These he downloaded in exchange for the week’s production of cassiterite concentrate (six to ten buckets, if my memory serves me).

Tin fetched high prices in 1969 and was much more profitable than gold. The buying rate for tin was posted daily on a chalk board in the Marble Bar pub – the “Hot and Cold” (hot outside: cold inside – the bar possessed the only air conditioner within a 200km radius).

[1] This was Noel Crichton-Browne, later (1981-1996) Liberal Senator for Western Australia in the Australian Federal Parliament.

(2) Technically, a granitic aplite.